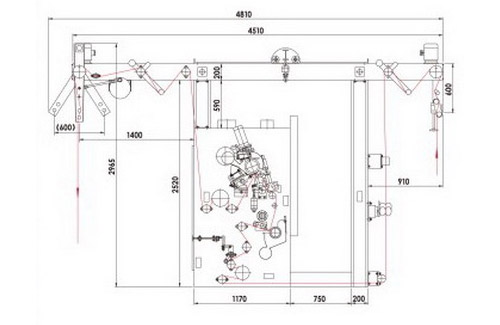

Application

There are three models of this machine: Model ME509A is mainly used for surface shearing of woven fabric such as leather based cloth and so on. ME509A(C) is suitable for shearing of knitting fabric, curls, hairiness or thread end on the surface of weaving, towel fabric, loop fabric and decorating fabric. Model ME509A(M) is used in surface shearing of woolen and worst fabrics.

Feature:

- 1. Shearing Cylinder can be adjusted variably by inverter, with traversing device and grinding blade on the machine is realized. The shearing blades are universal use with model ME503 breed of shearing machines.

- 2. Adopted swing fabric table seat when meet fabric seam which makes sturcture action more stable, avoided shock motion and distortion of shearing blade.