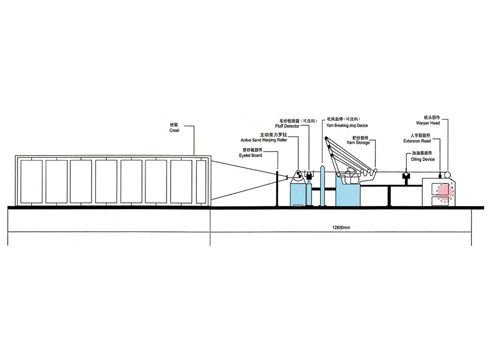

Product Description Introduction

This machine adopts computer real-time online copy systeam and ensures the constant tension control. Original asynchronous servo motors enable the yarn tension to be with less undulation inspite of the tension deviation of different yarn bobbin sizes and save much more raw materials because of the consistency of same lot beams. It is suitable for filament yarns, dty, pty yarns and staple fibre yarns, etc.

Main Features

1. Intelligent real-time monitoring copy function can compensate the tension differences of different bobbin sizes and enables the same lot beams to be with the consistent lap numbers ,meters, girth and weight.

2. Embedded software based on wincc ensures the clear picture displayed.

3. With beam copy function, consistent beams can be made according to original beam data.

4. Beam and tailstock are stable and positioned with high pricise and easy to operate because of using double-axles pneumatic positioning method.

5. Using the latest SIEMENS Smart 200 industrial controller and modbus communication system improves the response speed of machine. • New model laser stop device with strong wind force is more sensitive and improves the warping quality.