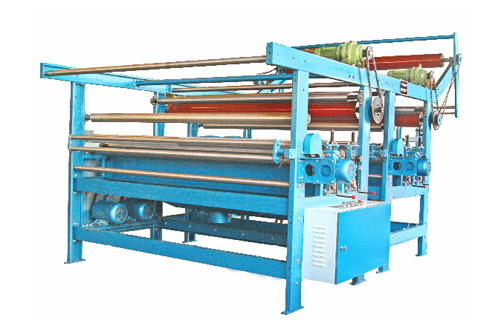

1.Application

This machine is suitable for surface raising of knitting fabrics, blanket, woolen, fur and carpet.

Structure :

This machine is made of frame, brushing parts and guiding parts.

2.1 Frame structure: Machine frame is welded by hot rolling 14a U-steel,the structure is strong and easy for assembling and disassembling.

2.2 Brushing parts: Two ends of brushing roller are supported by bearing seat and fixed on the frame,

driven by 3 phases motor, adjust the distance between fabric guiding seat and brushing roller by screw.

2.3 Guiding parts: made of planet-cycloid retarder, pull roller, fabric guiding roller and swing frame.

Main data:

Nominal width 2500 (mm)

Production capacity 15mm/min (variable)

Brushing roller rotating speed 1000 fore /1100 rear

Diameter of rushing roller Ф156

Number of rushing roller 4pcs

Motor power 25kw(not include dust exhaustor)

Spreading roller power 3kw (opt. parts)

Working voltage 380V

Brushing roller bearing temperature rise ≤30℃

Noise level ≤80db(A)

Overall dimensions(L×W×H) 4650×3700×3060

Machine weight 2T