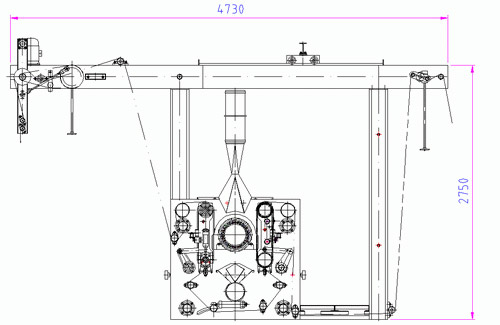

Application:

This machine is suitable for surface polishing of natural and chemical fiber, knitted and gregarious fabrics. It is mainly used for processing of ordinal woolen, blanket, warp knitting fabrics, micro velboa and knitted non-pressed-pile. Its working efficiency is nearly twice as the ordinary polishing machine.

This high quality MB432 polishing machine is easy to operate and reliable with the following features compared to the congeneric machines:

- 1. Double polishing rollers double table lathes have good effect. The working efficiency is nearly twice as the ordinary polishing machine. The fore polishing roller is possible to run forward and reverse, polish velvet velludo when anticlockwise and polish velvet plain clockwise. Adopted big diameter polishing roller with large heat capacity. The working