2.Main technical data

ITEM

|

DATA

|

Nominal width(mm)

|

2000

|

2500

|

2800

|

3200

|

Fabric speed(m/min)

|

10~40 infinitely variable

|

Drum speed (r/min)

|

60~90 infinitely variable

|

Roller dia.(mm)

|

φ70

|

Number of roller(pcs)

|

36

each 18 for pile roller and counter pile roller

|

Motor power (not including blower and air compressor )(kW)

|

42.4

|

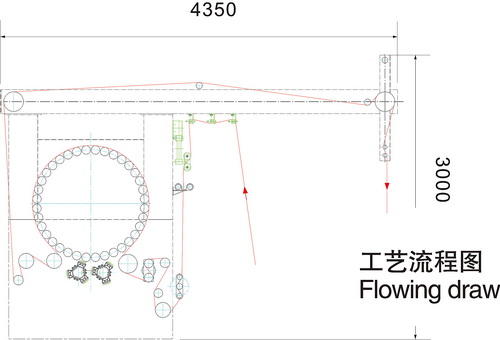

Overall Dimensions(mm)

L×W×H

|

4110

4690

2840

|

4110

5190

2840

|

4110

5490

2840

|

4110

5890

2840

|

3.Feature

3.1 The level of an organic whole of machinery and electric equipment is very high, controlled by man-machine conversation, PLC and 7 inverters.

3.2 Driving system with inverter-controlled multi motors.

3.3 Drum speed, fabric speed, fabric tension and raising power are freely adjusted in a large scope.

3.4 Driving V-belt of raising rollers are controlled by pneumatic, the tension of belt can be kept constant.

3.5 100 sets of processing parameter can be stored.

3.6 Set up the parameter in running, zero starting, automatic fabric feeding and reversing are available.

3.7 Trouble alarm and diagnosis are available.

3.8 Centering device, fabric reverse device and automatic-stop parts are optional when processing different fabrics.

3.9 It is possible to create continuous raising line or raising and shearing line, set fabric storage chamber between the single unit.

Highlight

1 The increased power is helpful for the fabric which is hard rasing, the efficiency is improved greatly.

2 Simplified roller driving chain makes maintenance easier and less wearing parts

3 Roller adopts unloading load-type structure, not only improve the lifetime of the bearing, but also greatly reduce the possibility of roller shaft fracture.

4 Two pieces (micro-velboa recommended) or three pieces (warp-knitted velvet recommended) of spreading roller parts, adjusted by inverter to suit various fabric expanding requirements.

5 Less driving chains on the right side of the machine, more convenient to replace V-belt.

6 To control cylinder fore fabric tension more stable, set double brake rollers structure (only when choose two pieces of spreading roller parts).

7 Cylinder rear guiding roller adopts double guide roller structure, and the distance with cylinder can be adjusted, to get the different style. Using a pair of meshing gear transmission, good stability.

8 Wind pipe arrangement is very convenient, air outlet on right side or left side of the machine.

Optional parts

1 Pre-spreading device THB1100

2 Centering device THB1200

3 Automatic stop when lack of fabric

4 Fabric storage chamber

5 Fabric reversing device (Q and H type 200 series)

6 Pressing roller device

Note: Drying roller is a special part for customization.